News

A Dutch concrete factory is looking for a sustainable alternative for polyethylene foam for the protection of concrete plates

Actualité proposée par Caroline Kolb, de la CCI Grand Est

A Dutch concrete factory is looking for a sustainable alternative for polyethylene foam for the protection of concrete plates

https://een.ec.europa.eu/partners

Description du projet :

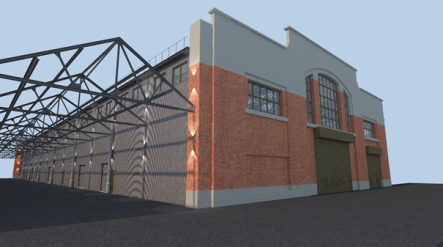

The Dutch concrete factory was founded in the 2004 and is now one of the leaders in the production of a large variety of prefabricated concrete elements; from structural walls to columns or floors. The different concrete elements are stocked and then transported to the customers. For this logistical process specific spacers are used, in the industry these are known as “hands” or “fists”. The spacers ensure that the elements to be stored and or transported do not come into contact with each other and thus cannot be damaged. The spacers are U-shaped, made of hot-dip galvanized steel. To prevent damage to the concrete elements, the U-shaped spacers are currently covered with a strip of polyethylene foam. From a sustainability point of view, the polyethylene foam strips / pads do not contribute to the sustainable strategic goals of the SME. In principle the foam pads are for one-time use. After transport they are thrown away, or worse; they are strewn around the construction site. Lots of them are spread by the wind and thereby are a burden to the environment. The present used material of the protection strips is not degradable and thus can pollutes the construction site and the environment. Enforcement agencies are also drawing the company's attention to this fact more and more frequently. This is obviously not desirable, because the SME wants to be the greenest concrete factory in the Netherlands. As the concrete manufacturer believes that it is their responsibility to find reliable, efficient and effective ways to reduce waste and increase the recycling of materials. The company is looking for a solution to cover these spacers "on site" in a robust and sustainable way so that they permanently substitute the properties of the present foams. Sending the spacers off to a factory that can cover them is not an option. Fitting the protection cover, the spacers (“hands”) must be possible on site. In this respect the company is looking for innovative solutions for lining the spacers or alternatively create an new type of spacer .

Partenaires recherchés :

The concrete factory is looking for suppliers that can provide innovative and creative solutions to replace the presently used foams with a sustainable material. The SME is looking for a solution to cover the clamps / hands "on site" in a durable way so that they permanently have the properties of the presently used foams. Fitting the foam covers must be possible on site. The following expertise is sought: • Chemical and mechanical properties of protective foams • Tech & design: • Creative thinking • Design/ Sustainability

Nature du partenariat :

Technique et commercial

Modalités et contacts :

Cette opportunité de partenariat est issue de la Partnering Opportunity Database (POD) accessible sur le lien ci-après :

https://een.ec.europa.eu/partners

Cette base de données d'annonces gratuites et anonymes a été créée par la Commission européenne pour les entreprises et son réseau Enterprise Europe Network (EEN), dont la Chambre de Commerce et d'Industrie Grand Est fait partie. Cette source de contacts s’appuie sur un réseau de 600 organisations membres du réseau EEN et localisées dans 67 pays. EEN est créé et co-financé par la Commission européenne afin d'accompagner les PME à l'innovation et à l'internationalisation. L'annonce est sujette à modification. Pour tout complément d'information et demande de mise en relation avec l'entreprise ayant publié cette annonce, contacter Caroline KOLB T. 03 88 76 42 37 - M. 06 84 42 53 52 - ca.kolb@grandest.cci.fr

Mots clés :

mousse durable

Aucun commentaire

Vous devez être connecté pour laisser un commentaire. Connectez-vous.